VENTIVA’S REVOLUTIONARY ICE® TECHNOLOGY

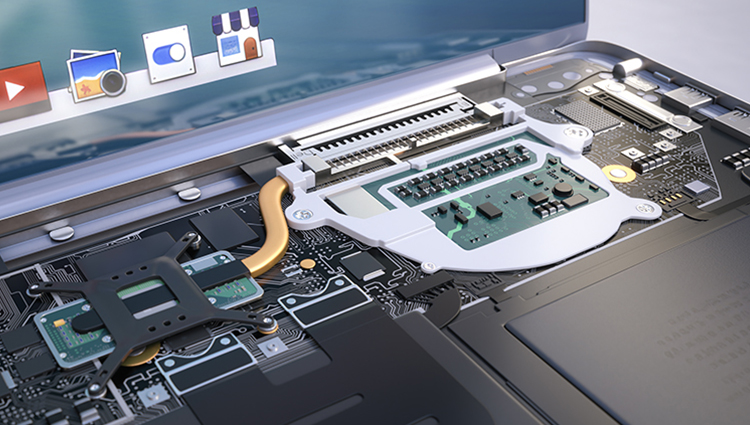

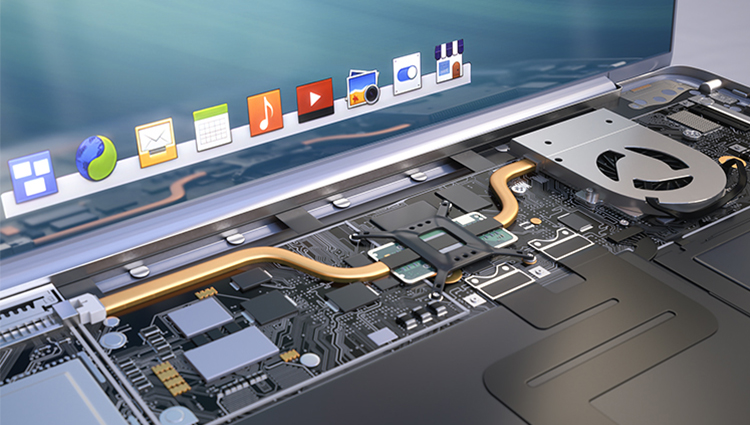

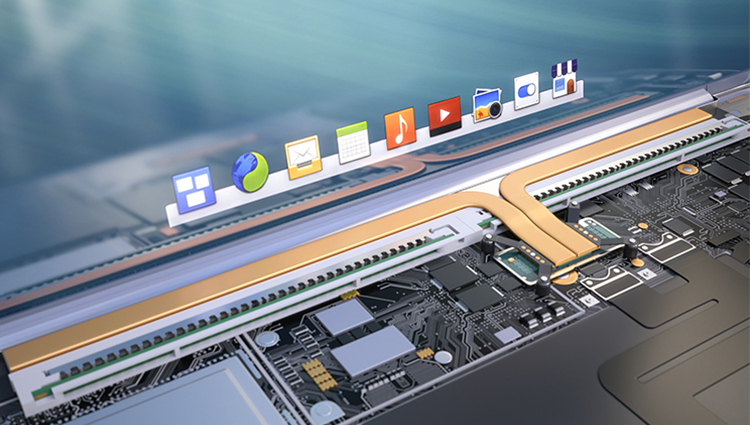

Ventiva’s Ionic Cooling Engine (ICE®) represents a quantum leap in thermal management technology. The ICE® technology moves air in a unique way, without moving parts, noise or vibration. Built on the principle of electrohydrodynamic airflow, ICE® harnesses the power of a minuscule plasma field to generate movement of air particles, delivering a potent “solid-state” cooling force suitable for up to 30-Watts Thermal Design Power (TDP) systems. Ventiva’s ICE® technology is a paradigm shift that is revolutionizing thermal management for a new era of lightweight, ultra-compact, vibration-free, and utterly silent electronic devices.